導入

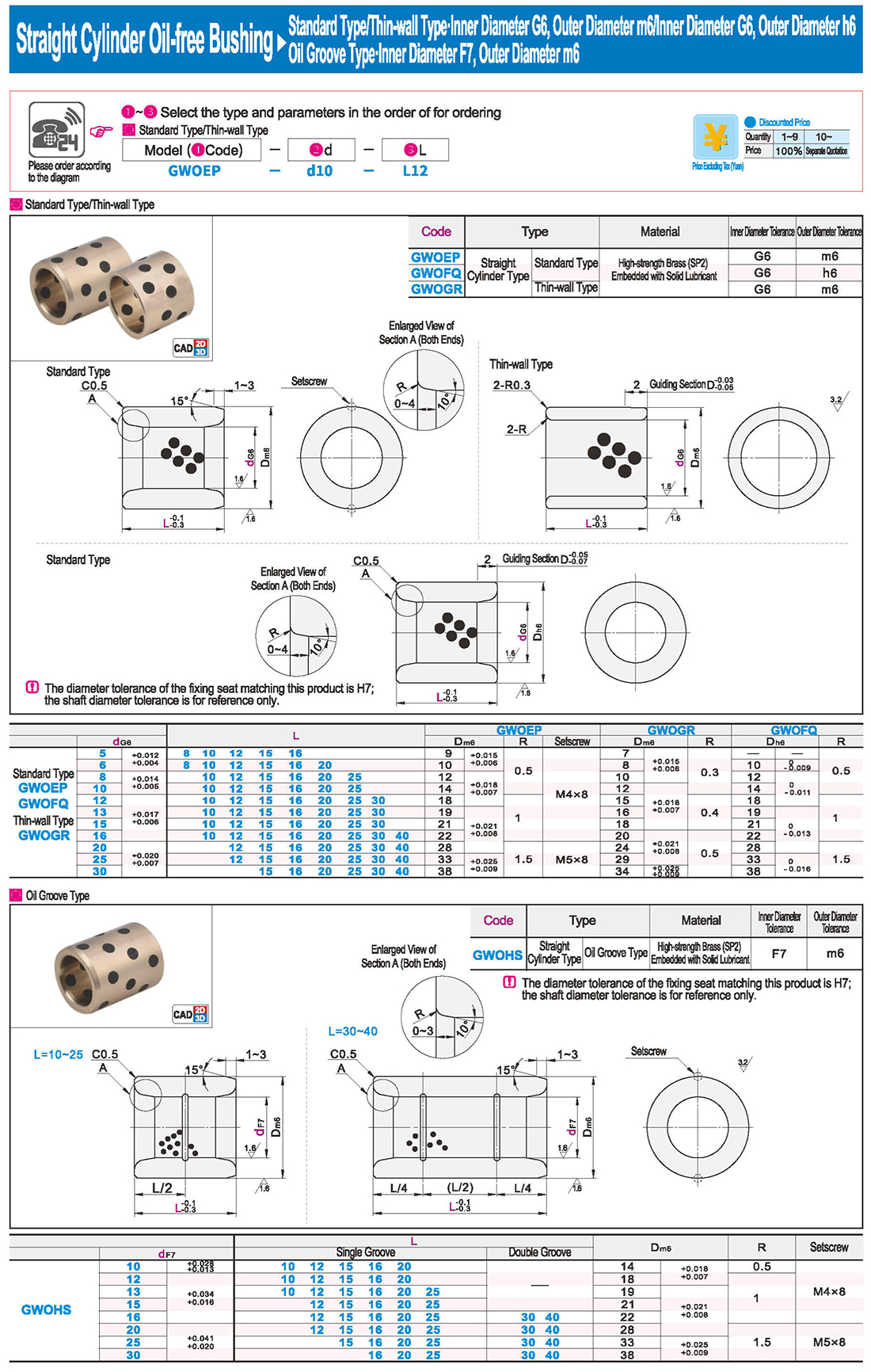

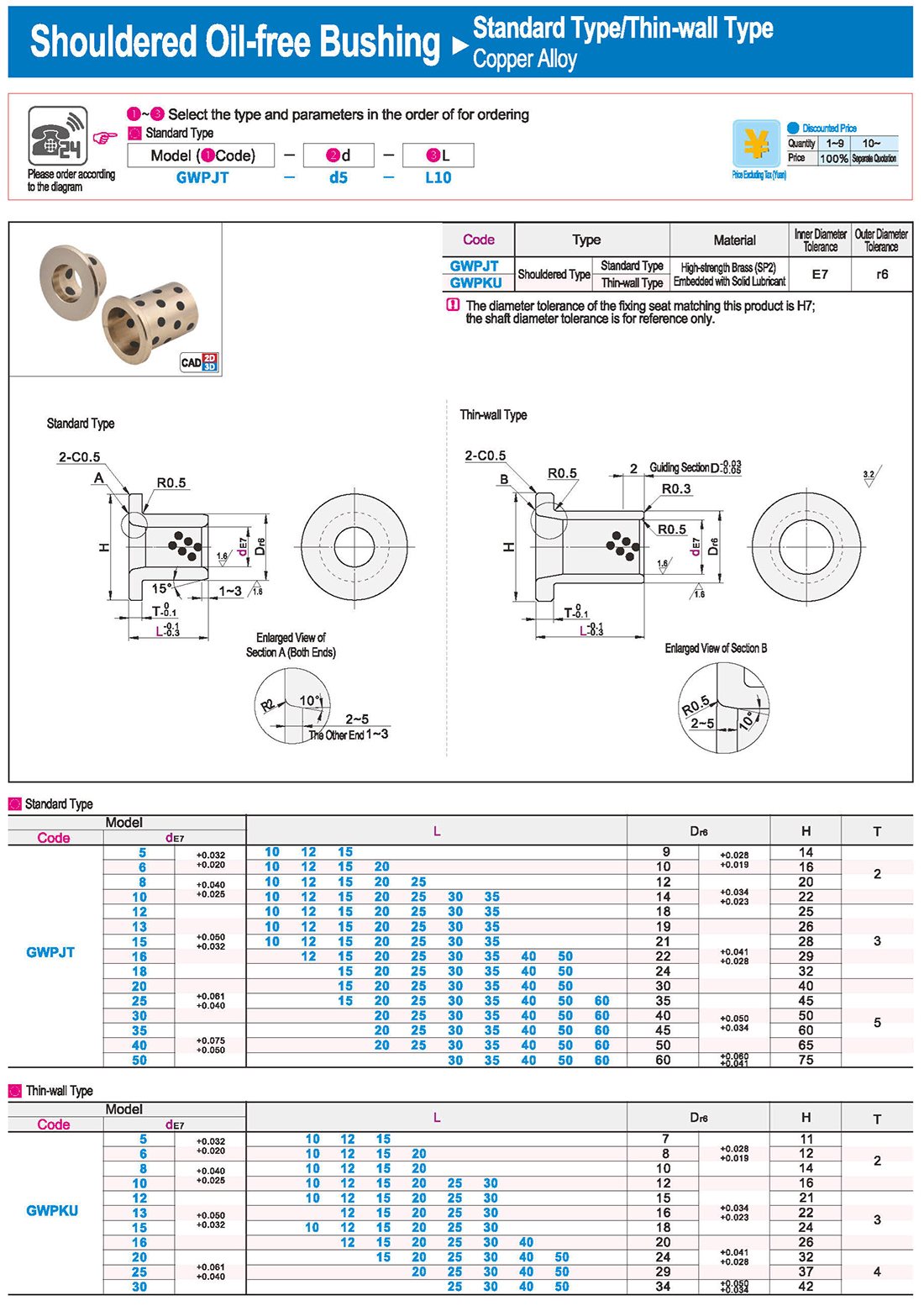

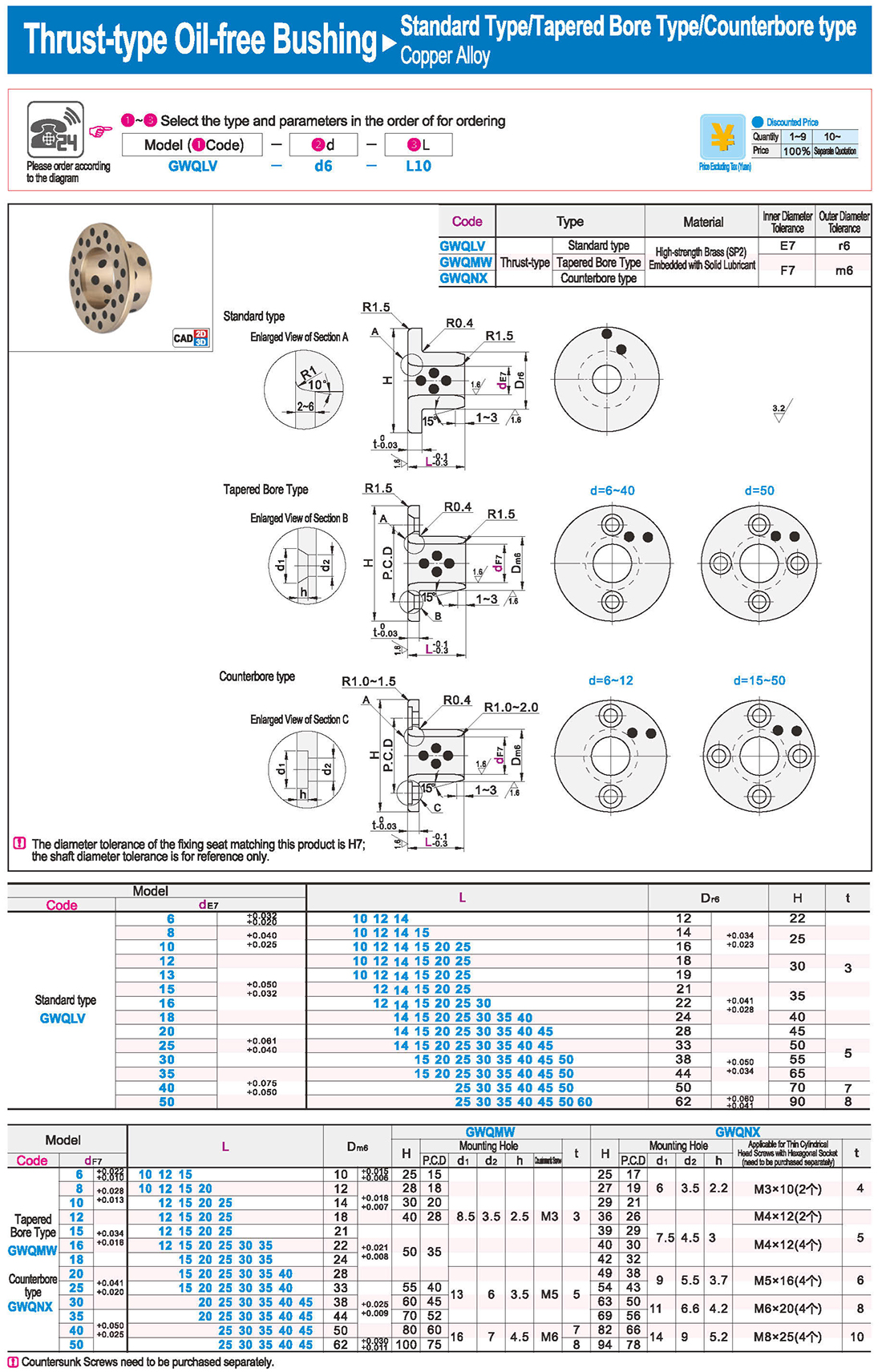

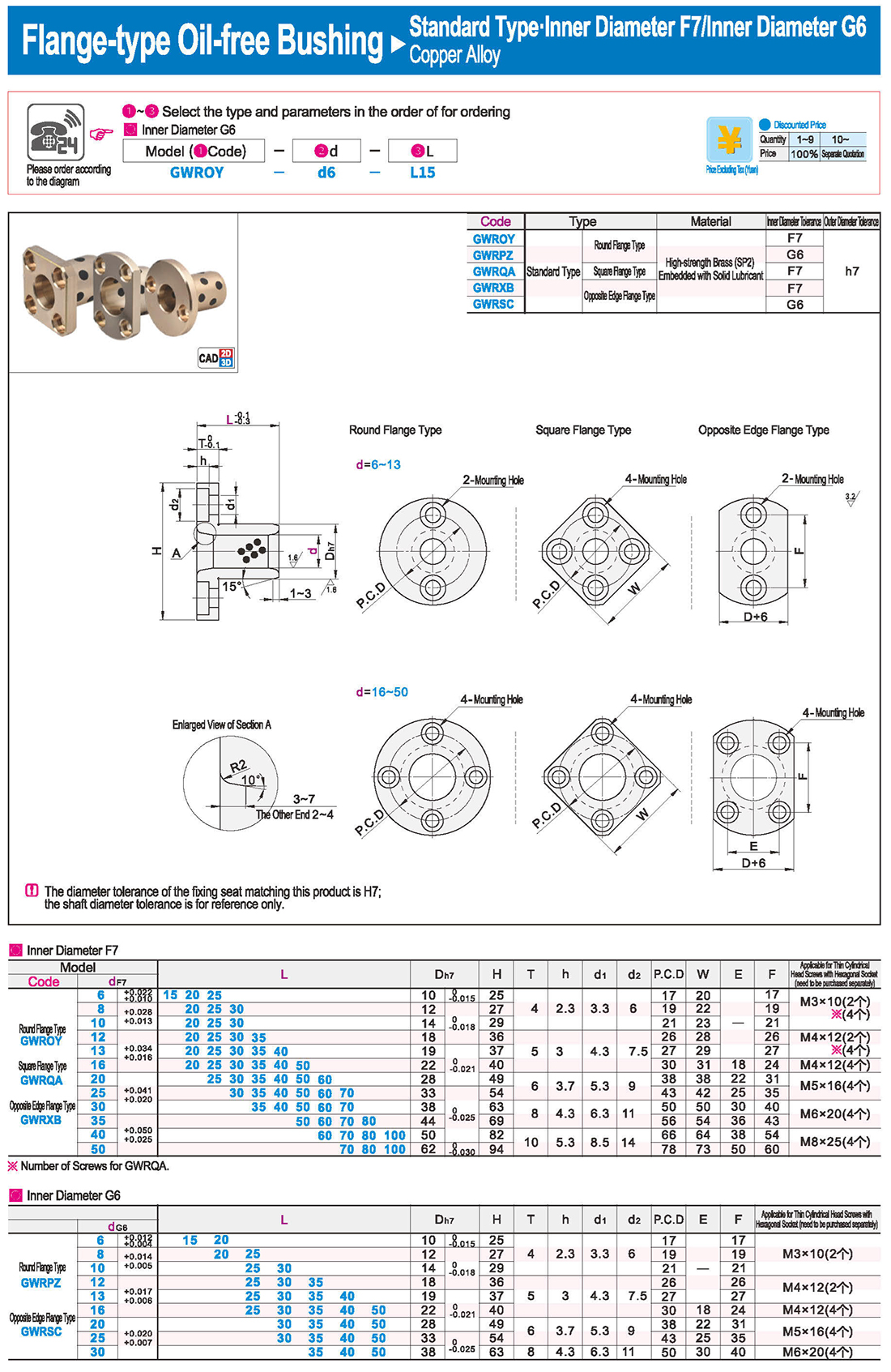

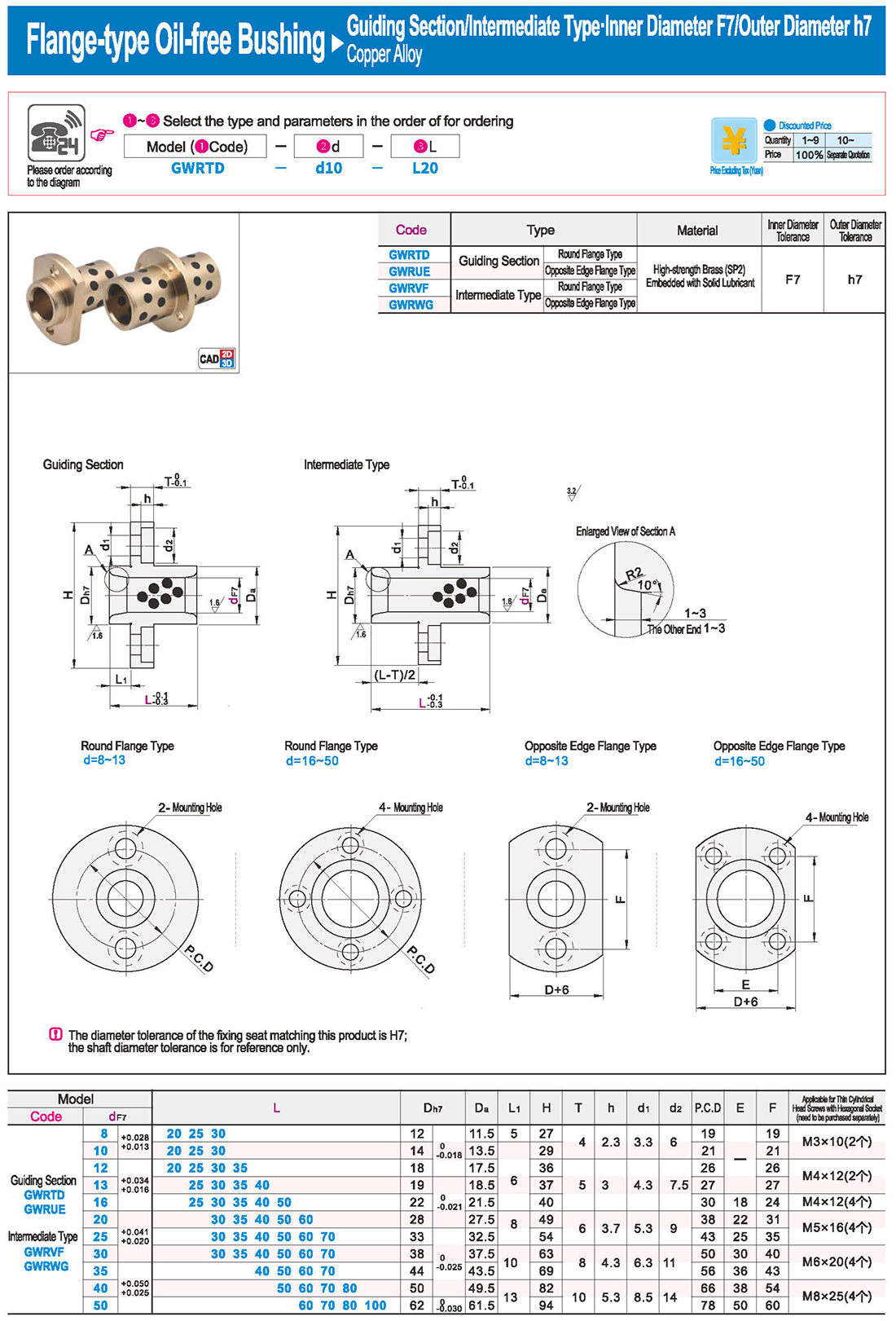

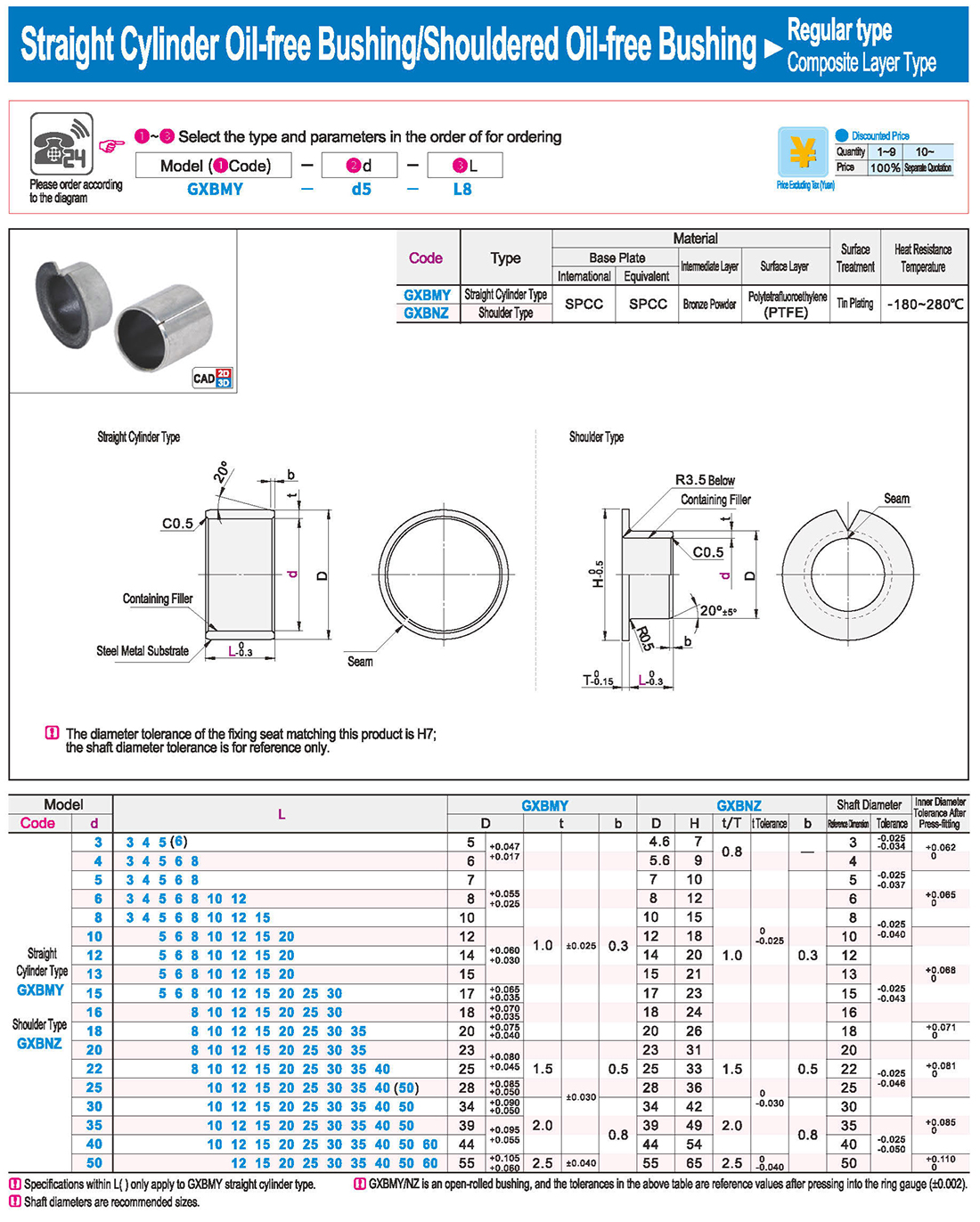

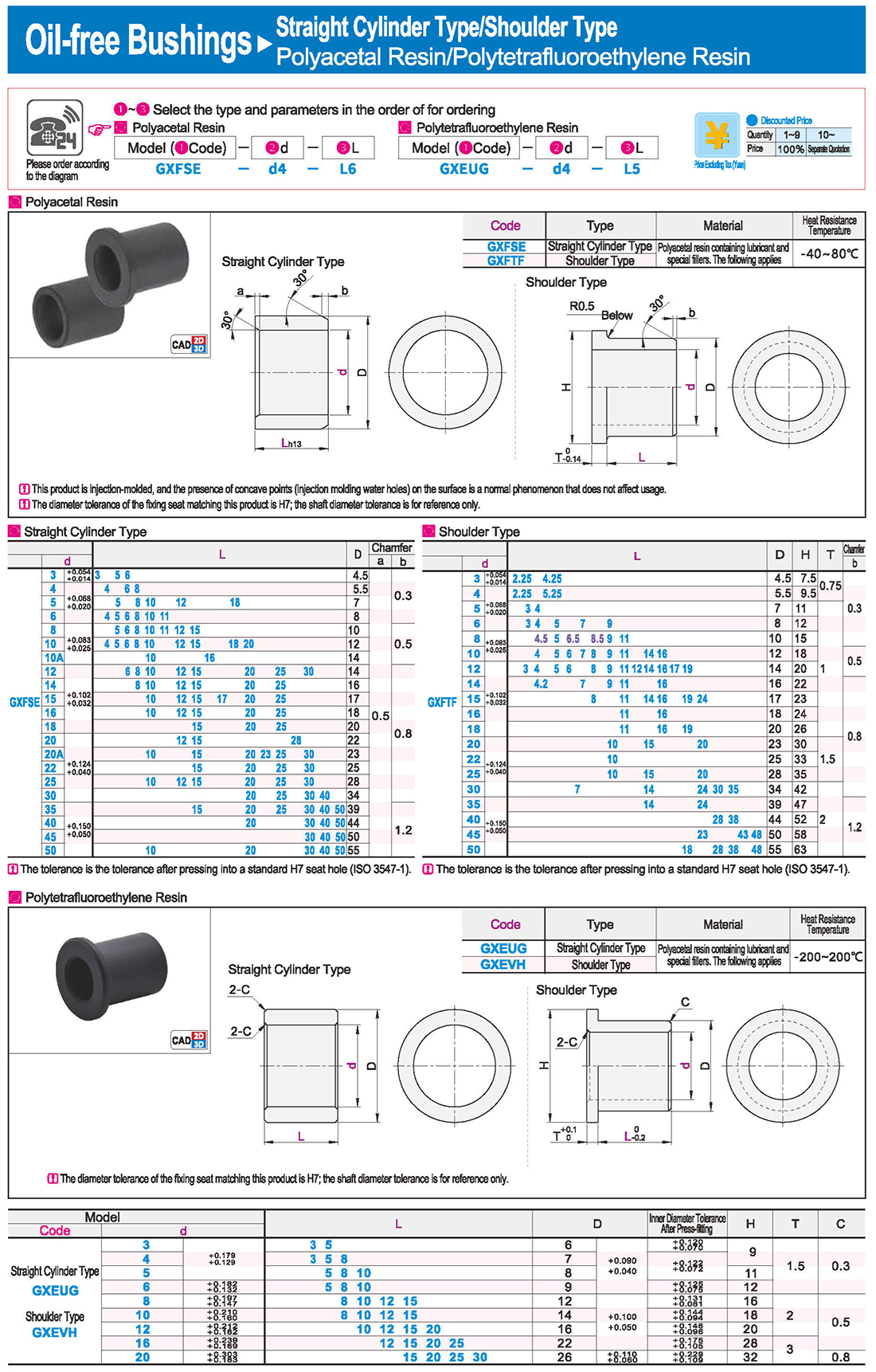

導入 仕様テーブル

仕様テーブル ダウンロード

ダウンロード無油ブッシング-製品紹介

無給油ブッシュは、自己潤滑軸受とも呼ばれ、金属軸受と無給油軸受の特性を組み合わせた新しい潤滑軸受です。この負荷を担う金属基材と、潤滑機能を持つ特殊な配合の固体潤滑剤で構成されています。高耐荷重性、耐衝撃性、耐高温性、高い自己潤滑性を有しています。特に、重荷重、低速、往復運動または揺動運動、その他潤滑が困難な用途や油膜形成用途に適しています。また、水の洗浄や他の酸性液体の浸食や精練にも耐性があります。現在、これらの製品は、冶金連続鋳造機、鋼圧延設備、鉱山機械、金型、昇降機、繊維機械、風力発電、船舶、蒸気タービン、水タービン、射出成形機、生産ラインに広く使用されています。

Installation Considerations

①Before assembly, ensure that the surface of the bushing and the seat hole are free of foreign objects. The surface of the seat hole should be as smooth as possible to prevent scratching during assembly.

② During assembly, lubricant can be applied to the outer surface of the bushing to assist in its easier installation, but not too much to prevent the bushing from dislodging during heavy loads or reciprocating motion.

③ Use a mandrel to slowly press the bushing into place during assembly (hydraulic press recommended). Direct hammering of the bushing is prohibited to prevent deformation.

④ If the seat hole design involves the use of easily deformable materials such as aluminum alloy or if the wall thickness of the seat hole is relatively thin, please provide clarification to prevent deformation during press-fitting.

⑤ To simplify assembly and avoid damaging the wear-resistant layer, the end face of the shaft must have a chamfered and smoothly transitioned edge. It is recommended that the shaft material be bearing steel with a quenched surface treatment of HRC45, a surface roughness of Rz2-3, and the surface can also be hard chromium plated.

Selection Steps for Oil-free Bushings

Determine Operating Conditions → Preliminarily Select Specification → Verify Basic Safety → Complete Selection

Determine the operating environment, general usage, heat resistance, chemical resistance, load capacity, frequency of use, and the need for lubrication.

Select the appropriate type such as straight pillar or shoulder-type. Pre-select the specification and size based on the design conditions.

Maximum Allowable Load: Please confirm that the load is within the maximum allowable load limit.

Maximum Allowable Speed: Please verify that the moving speed is within the maximum allowable speed limit.

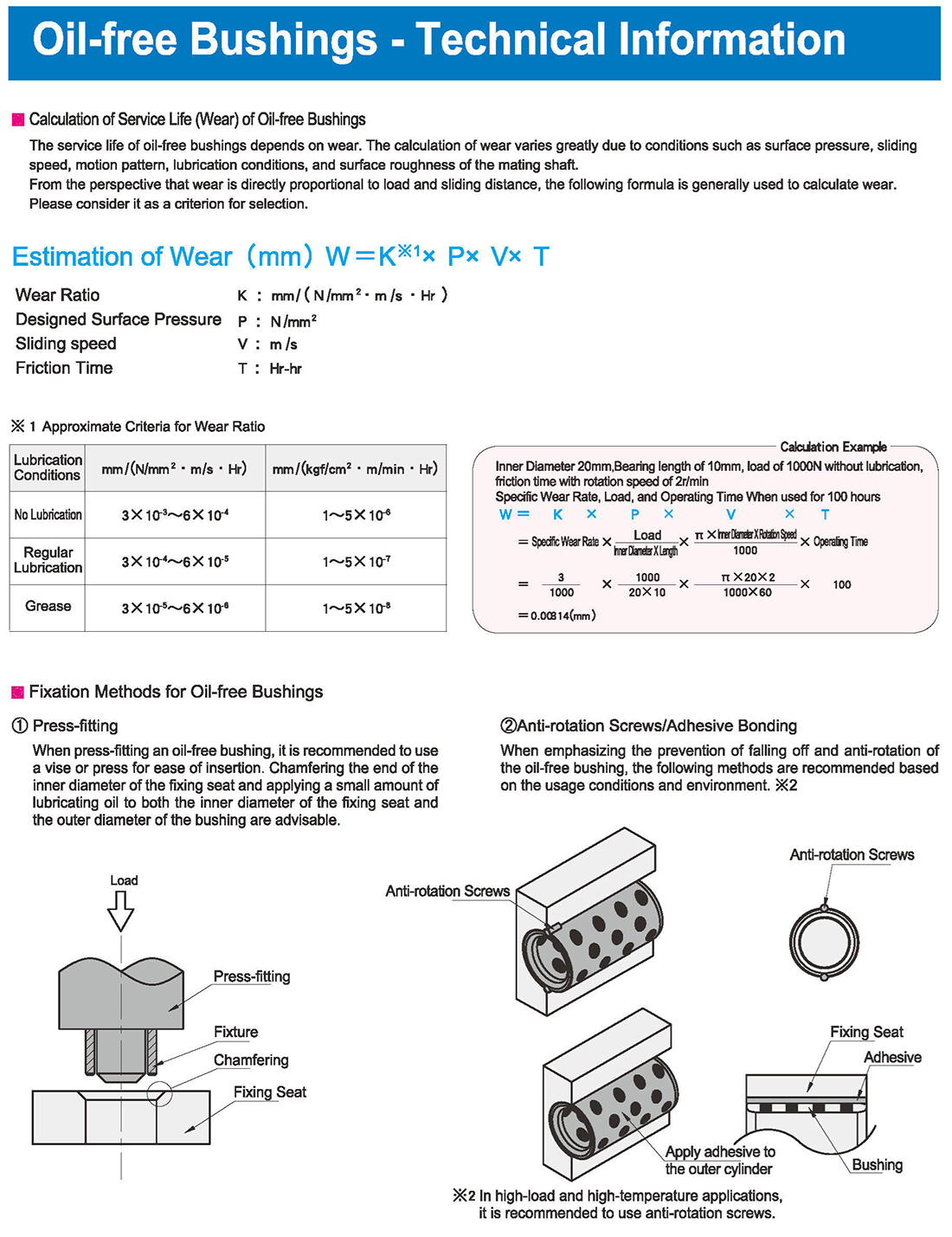

Lifespan (Wear Calculation): Calculate the approximate wear amount and confirm that the necessary lifespan can be ensured.

Fixation Methods for Oil-free Bushings

Press-fitting

When press-fitting an oil-free bushing, it is recommended to use a vise or press for ease of insertion. Chamfering the end of the inner diameter of the fixing seat and applying a small amount of lubricating oil to both the inner diameter of the fixing seat and the outer diameter of the bushing are advisable.

Anti-rotation Screws/Adhesive Bonding

When emphasizing the prevention of falling off and anti-rotation of the oil-free bushing, the following methods are recommended based on the usage conditions and environment. ※2

Press-fitting Fixture, Bushing, Chamfering, Anti-rotation Screws, Adhesive, Apply adhesive to the outer cylinder

In high-load and high-temperature applications, it is recommended to use anti-rotation screws.

Strengths of Oil-free Bushings

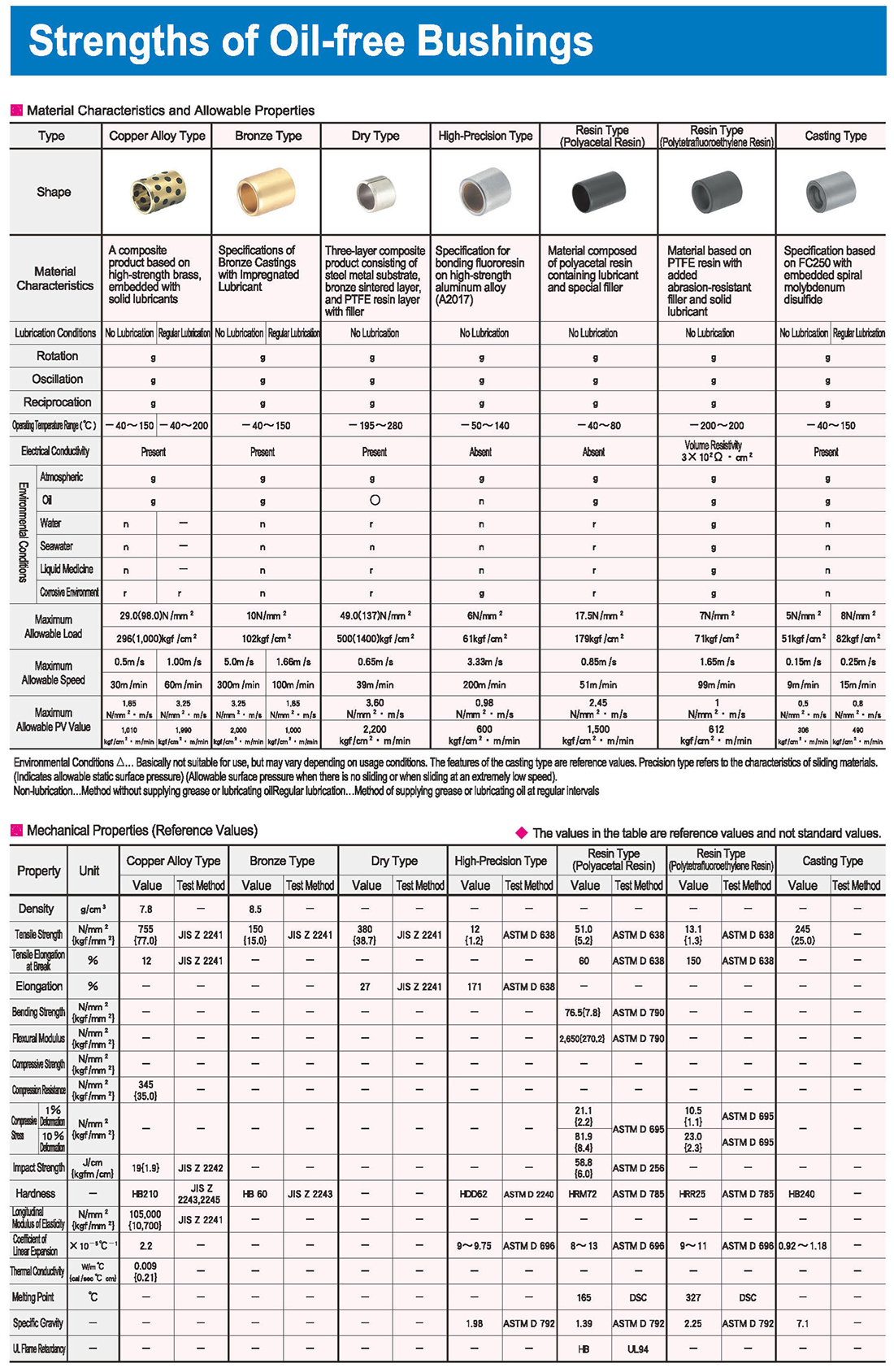

Material Characteristics and Allowable Properties

Copper Alloy Type, Bronze Type, Dry Type, High-Precision Type

Resin Type (Polyacetal Resin), Polytetrafluoroethylene Resin, Casting Type

Material Characteristics

A composite product based on high-strength brass, embedded with solid lubricants

Specifications of Bronze Castings with Impregnated Lubricant

Three-layer composite product consisting of steel metal substrate, bronze sintered layer, and PTFE resin layer with filler

Specifications of High-strength Aluminum Alloy

Material composed of polyacetal resin containing lubricant and special filler

Material based on PTFE resin with added abrasion-resistant filler and solid lubricant

Specification based on FC250 with embedded spiral molybdenum disulfide

| 分類 | タイトル | ダウンロード |

|---|---|---|

| fa産業自動化ワンストップサービスプラットフォーム |

やあ!おかえり。

お元気ですか?